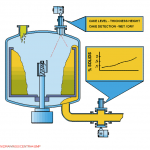

Canty offers a unique vision based approach for non-contact cake detection and level measurement designed for Nutsche Filters. Cake detection is the determination of the transition from liquid slurry to solids “cake”. It’s critical to determine this transition in a timely manner to avoid cracking in the cake layer. Cracks will cause inconsistent washes and lost product. CANTYVISIONCLIENTTM software performs cake detection with image analysis in real time, by identifying the transition and generating an output signal for control to produce a homogeneous product without washing it away (through 4-20mA, OPC Interface, Modbus, etc…). Simultaneously, level measurement can be performed with the same vision system and crystallizer efficiency can be calculated. Combine this with an in-line Canty CrystalscopeTM for true size and shape of crystals as they grow in real time for total process control. Operators can view the process at all times for visual verification and results are archived for historical record.

Nutsche Filter

Additional Information

| option | Process Control |

|---|

Documentation

Your browser is out-of-date!

Update your browser to view this website correctly.Update my browser now