GAME CHANGING INNOVATION FOR SIL RATED

OVERSPEED PROTECTION

SpeedSys 200 is a high-integrity overspeed protection system for rotating machinery. It delivers the core layer of protection with a compact architecture. Its small technical footprint and low-impact installation enables advanced protection to a wide range of applications. The simple and robust design meets the latest safety standards, and features easy maintenance and long proof test intervals

SpeedSys® 200 Overspeed Protection System

Additional Information

| option | Over Speed Protection, Speed Monitoring, Speed Transmitter |

|---|

Documentation

Product Description

GAME CHANGING INNOVATION FOR SIL RATED OVERSPEED PROTECTION

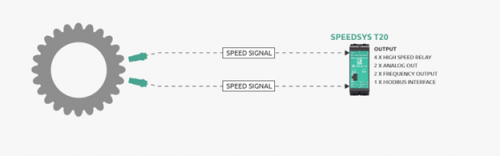

SpeedSys 200 is a high-integrity overspeed protection system for rotating machinery. SpeedSys 200 is a SIL-rated overspeed detection system for rotating machinery. It delivers the core layer of protection with a compact architecture. Its small technical footprint and low-impact installation enables advanced protection to a wide range of applications. The simple and robust design meets the latest safety standards, and features easy maintenance and long proof test intervals.

ADVANCED PROTECTION FOR A WIDE RANGE OF APPLICATIONS

Overspeed, underspeed and acceleration protection

for critical and semi-critical rotating machinery

Designed for versatility and scalable to the

application

Suitable for API 670 and API 612 applications

The API Standard 670 is an industry standard and describes the minimum requirements for a machine protection system (MPS). This includes, measuring radial shaft vibration, casing vibration, axial shaft position, shaft rotational speed, piston rod drop, phase reference, overspeed and critical machine temperatures.

The standard includes requirements related to hardware (sensors and systems), installation, documentation and testing. In this article, we focus solely on the part that describes overspeed and limit ourselves to this standard. The main elements are described.

The definition of overspeed

Overspeed occurs when the rotational speed of a rotating machine, such as a steam or gas turbine, exceeds its design limits. The consequences of an overspeed event vary per type of machine and per model. The time that the overspeed event lasts and the degree of overspeed relative to the design limit are also decisive for the consequences.

Even though manufacturers usually give the machinery a certain safety margin in the design with regard to exceeding the maximum rotation speed, an overspeed event can lead to rapid and impactful damage development. To prevent this, it is important to equip the machine with an overspeed monitoring system.

Update your browser to view this website correctly.Update my browser now