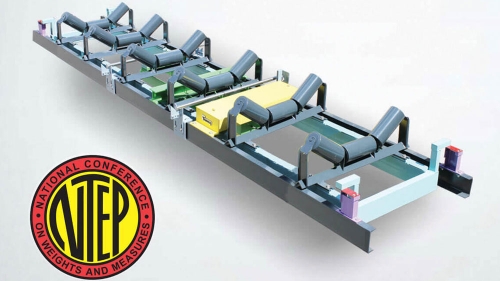

Thayer Scale’s conveyor belt scales & conveyor weighing systems are designed for a range of accuracies: high accuracy loading and unloading systems, custody transfer and NTEP-approved versions (0.10% – 0.125%), inventory control and processing needs (0.25% – 0.5%), and various stone and aggregate applications (0.5% to 1%). Customers in fertilizer, mining, ore, copper, and coal industries utilize our conveyor belt scales in severe applications and in some of the harshest manufacturing environments. Other industries, including pulp and paper and tobacco processing, use our belt scales for light-loading applications. These examples illustrate how our standard designs can support a wide range of belt scale applications with only minor modifications.

We offer many special configurations with our conveyor weighting system (conveyor belt scales) and scale prices; designed for light-scale loading of materials such as biomass, wood chips, saw dust, tobacco and MSW. We build 1, 2, 3, 4, 6 and 8 idler belt scales supporting belts from 14 to 96 (and over) inches wide.